Efforts for Realizing a Low Carbon Society

Green Technology System Division

Taikisha is helping to reduce GHG emissions at the operation phase of the air-conditioning and sanitary facilities it provides to clients.

Eco-Friendly Design

The Green Technology System Division promotes initiatives to reduce environmental impact and realize a sustainable future. Particularly, the division contributes to CO2 emission reductions by increasing the efficiency of clients’ facilities through eco-friendly design with an emphasis on energy saving.

The eco-friendly design starts with an energy-saving diagnosis to grasp the current status. In this diagnosis phase, we analyze the energy usage of clients’ current facilities in detail to identify waste. Based on this as well as clients’ future visions, we propose specific energy-saving measures. This proposal includes the implementation of the Energy Plant Optimal Control System which is based on simulation data and realizes optimal operation control according to external conditions. The system maximizes energy-saving of heat source systems and thus helps reduce CO2 emissions and running costs.

In the design and installation phase, we incorporate the energy-saving proposals and utilize the latest AI and IoT technologies to improve the efficiency of air conditioning systems in factories and buildings. Specifically, we introduce various energy-saving technologies, including clean room systems that control the air conditioning by tracking the operation status of production equipment, staffing and indoor environment, as well as room pressure control systems and low-dew point systems. This allows the indoor environment to be maintained at optimal conditions while minimizing energy consumption.

Next, we evaluate the effectiveness of the implemented energy-saving measures to verify the effects in the operation phase. By repeating this cycle, we aim to make continuous improvements and pursue further energy saving.

We are proactively working on the eco-friendly design in overseas projects as well as in domestic ones. Especially in projects where electrical equipment is included in the scope of design and installation, we propose energy-creating solutions such as photovoltaic power generation to promote the use of renewable energy. In this manner, we achieve optimal energy supply in accordance with energy demand in each region, thereby contributing to CO2 emission reductions worldwide. We are also striving to improve the accuracy of the CO2 emission calculation. By understanding the actual reduction effects of each project more precisely, we are able to reflect these results in our future improvement measures.

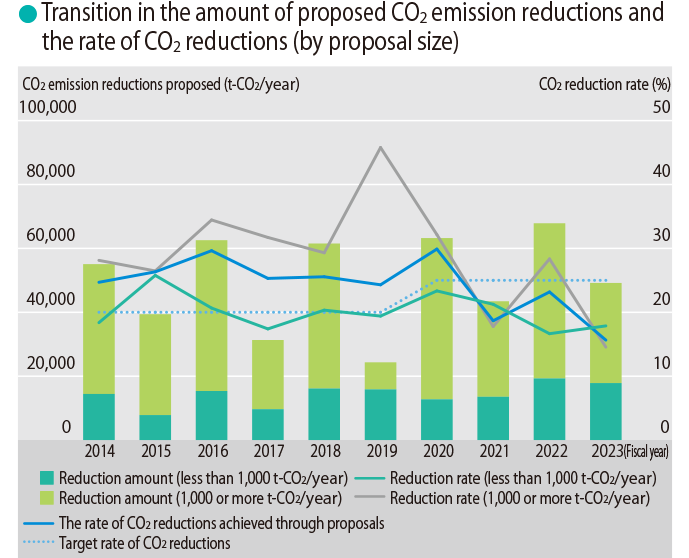

Along with these efforts, we evaluate the CO2 reduction rate for each fiscal year, which is the reduction rate of CO2 emissions from customerowned facilities enabled by our proposals. In FY2024, the number of proposals was 150, and the amount of proposed CO2 emission reductions reached 54,438 t-CO2/year. We set a CO2 reduction rate target of 25.0% or more on a weighted average for in-house design projects and achieved 20.9%. The proposed CO2 reduction amount equivalent to Category 11 of Scope 3 reached approximately 820,000 t-CO2 (the effect of 15 years of operation).

The Green Technology System Division will continue to work on energy-saving and environmental impact reductions of clients’ facilities by promoting eco-friendly design so as to contribute to the realization of a sustainable society.

- Target

- The CO2 reduction rate for in-house design projects (the reduction rate of CO2 emissions from customer-owned facilities enabled by our proposals): 25.0% or more on a weighted average

- Result

- 20.9%

Paint Finishing System Division

Taikisha is helping to reduce GHG emissions in the paint finishing process for automobiles, etc.

Achievements of the Company’s carbon neutrality initiatives and future targets

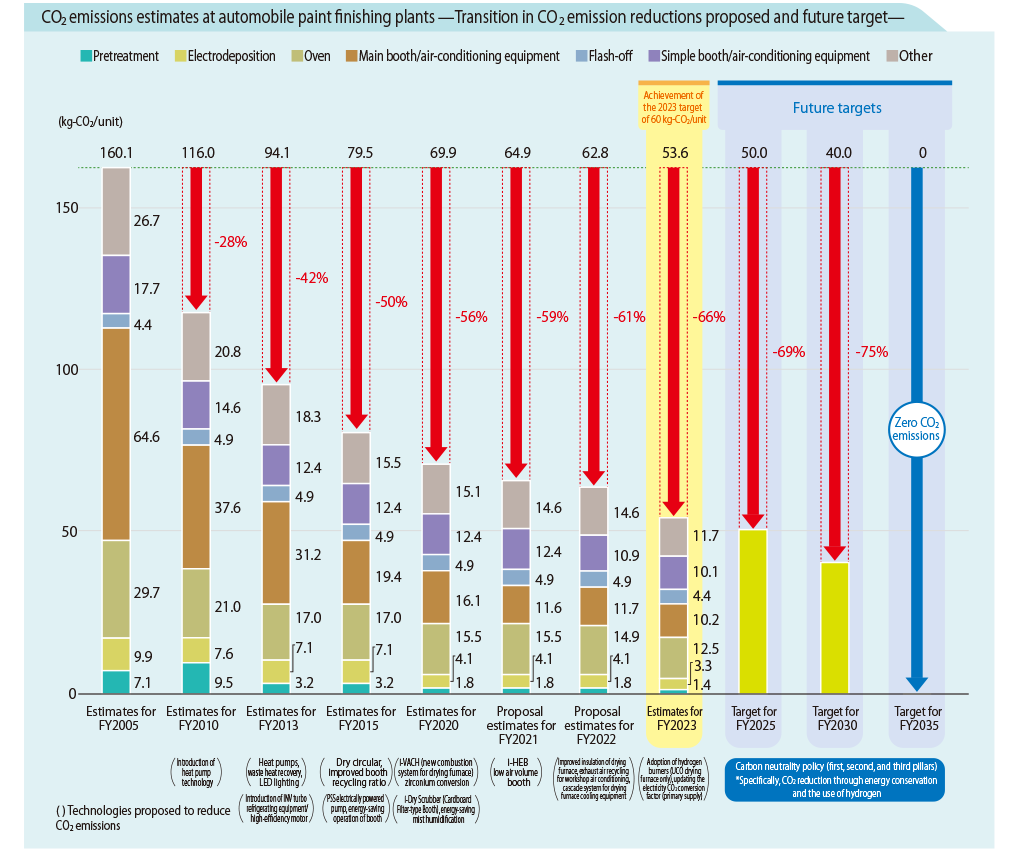

In the Paint Finishing System Division, we have been calculating and objectively evaluating the CO2 emissions per vehicle during the painting process in order to visualize the CO2 emission reduction effect by the technologies we have proposed. This evaluation is based on the energy estimation model for automobile paint finishing lines.

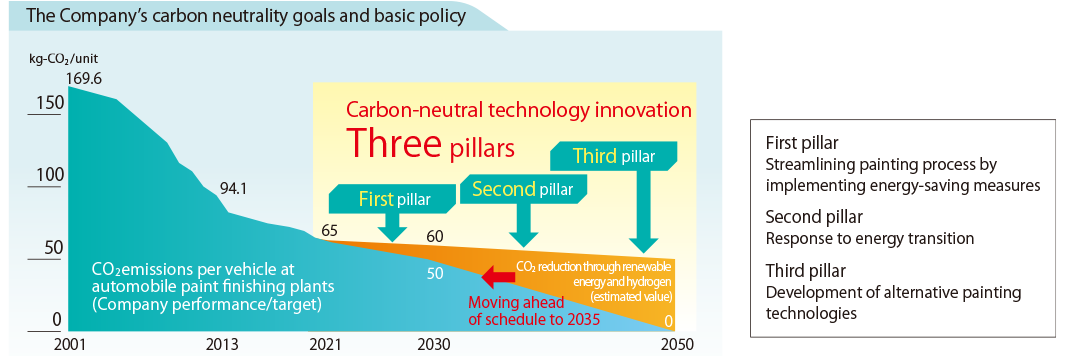

We have made various technology proposals to help reduce CO2 emissions, including the introduction of heat pump technology and high-efficiency equipment, and dry-type paint booths. Aiming to achieve carbon neutrality in automobile painting processes, since 2020, we have been developing technology under three pillars that represent our basic policy for technological innovation.

Based on the first pillar, we have proposed increasing paint coating efficiency, lowering the air volume of paint booths, and the development and improvement of indirect furnaces with VOC treatment functions to achieve highly efficient and waste-free production processes. In addition, we have been promoting further CO2 emission reductions by utilizing AI technology in production analysis systems with a view to minimizing production losses.

As a result of these initiatives, CO2 emissions based on the estimation model reduced to 51.4 kg-CO2/unit in FY2024, in contrast to 160.1 kg-CO2/unit in 2005.

As initiatives based on the second pillar, we have driven the use of electricity from renewable energy sources in painting facilities (all-electric facilities) and the use of hydrogen energy. We have also worked on the development of alternative painting technologies based on the third pillar, including the technological development of film decorating systems.

In advance of the global target of achieving net zero CO2 emissions by 2050, we have brought forward the target year and aim to achieve net-zero CO2 emissions by 2035. Our target includes the transition to renewable energy sources for the power supply. By backcasting from 2035, we have set interim goals of achieving 50 kg-CO2/unit by 2025 and 40 kg-CO2/unit by 2030.