Rotary RTO/Horizontal Rotary RTO

VOC Removal Technology

What is VOC removal technology?

We offer a wide variety of environmental protection devices, covers from various exhaust gas treatment systems and dust collectors to wastewater treatment systems. This section introduces exhaust gas treatment system to dispose organic gases from various plants.

- Want to prevent air pollution

- Want to reduce CO2 and enhance energy efficiency

- Want to make the best use of limited spaces

Rotary RTO (Regenerative Thermal Oxidizer)

Overview

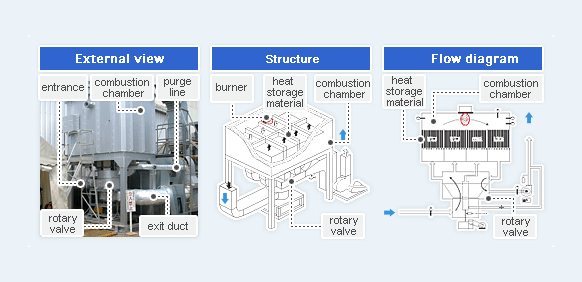

This exhaust treatment system includes a regenerative heat exchanger with rotary changeover valves.

It delivers a HC treatment efficiency of 99% or higher. The ratio of heat recovery volume is 95%.

The system can treat gases at the rate of 50 - 1000N㎥/min.

Rotary RTO (Mark III Experimental Unit)

Rotary RTO (Mark III Experimental Unit)

Features

-

Stable, high treatment efficiency and high heat recovery rate

Taikisha's Rotary RTO (vertical model) supplies and discharges treated air with a rotary distrubuting valve in a heat storage tower divided into eight sectors. It has a stable, high treatment efficiency and high heat recovery rate.

-

Reasonable cost

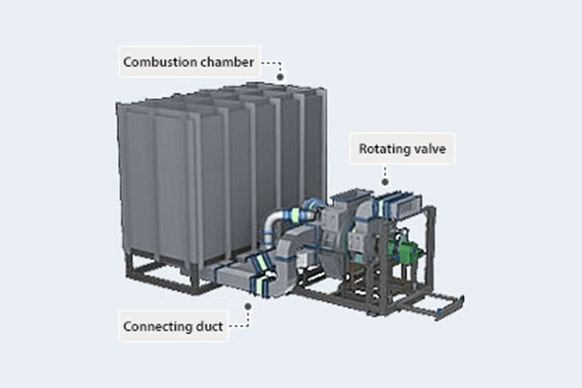

Taikisha started to provide Mark III from 2020. The Mark III achieves compactness by incorporating the connecting duct for the rotary valve and heat storage tower to the main unit. The installation period is shortened by adopting a unit construction. The rotary valve structure and materials were improved to enable Mark III to manufacture on-site. Furthermore, it has become possible to provide Mark III at a reasonable cost even overseas.

Specifications

Flow of Gas Treated with Rotary RTO

Watch a video that demonstrates the flow of gas treated with Rotary RTO.

Horizontal Rotary RTO

Overview

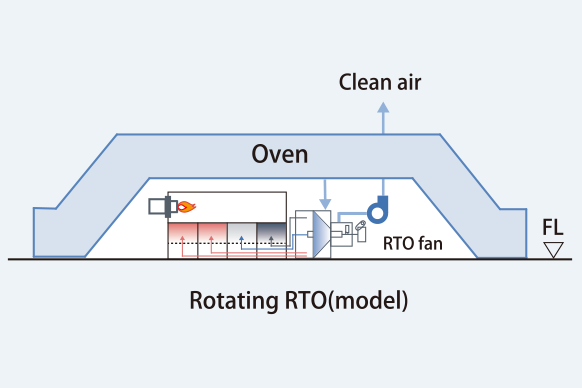

Horizontal Rotary RTO is Taikisha's new type of RTO with significantly reduced unit height by having a switching valve installed on the side of the conventional RTO main unit.

Lowering height enables it to be installed, for example, under a camel back oven in a factory and conserve indoor space for further efficient use. Moreover, it can contribute to total cost reductions including installation. This new type has followed the design concepts of the conventional Rotary RTO and offers as high an operational performance as the conventional product can offer.

Appearance

Appearance

Example of installation

Example of installation

-

*Patent registered

Features

-

Stable, high treatment efficiency and high heat recovery rate

Taikisha's rotary RTO (horizontal model: Mark II) supplies and discharges treated air with a rotary distrubuting valve in a heat storage tower divided into six sectors. It has a stable, high treatment efficiency and high heat ecovery rate.

-

Space saving

The Mark II is a space-saving type that particularly minimizes its height, allowing it to be placed in the combustor space under a drying oven. The treatment airflow volume is equivalent to one to two drying ovens, at 50 - 350N㎥/min.