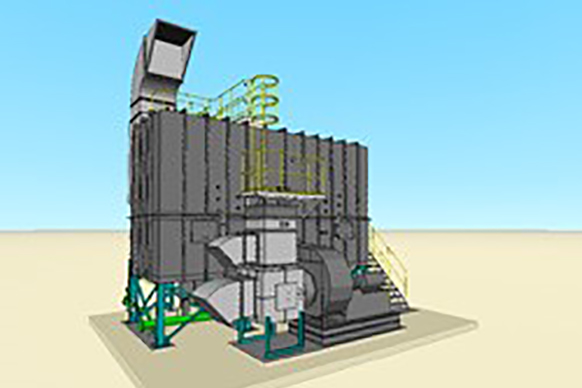

RTO (Regenerative Thermal Oxidizer)

VOC Removal Technology | Post-Processing Units

What is VOC removal technology?

We offer a wide variety of environmental protection devices, covers from various exhaust gas treatment systems and dust collectors to wastewater treatment systems. This section introduces exhaust gas treatment system to dispose organic gases from various plants.

What is post-processing units?

- Energy-saving technology that stores and reuses combustion heat waste in combustion type detoxification treatment for hazardous substances.

- Technology that can offer optimal incineration detoxifying treatment method for hazardous substances according to the exhaust conditions and treatment goals.

- Want to prevent air pollution

- Want to reduce CO2 and enhance energy efficiency

Overview

RTO is energy-saving system that oxidizes and decomposes VOCs (Volatile Organic Compounds) at 850°C or higher.

It is suitable for the treatment of high concentration gases and for use as a post-treatment unit to Admat.

RTO: Regenerative Thermal Oxidizer

Features

-

Durable & thermal-efficient deodorization system with ceramic heat storage material

A ceramic medium is packed as a heat storage material in the heat exchanger.

Our ceramic provides the benefits of high durability, thermal efficiency and low pressure loss.

The thermal efficiency is adjustable from 85% to 95%, allowing minimized energy consumption and requiring little supplemental fuel to deliver the greatest impact in energy savings.

With the target exhaust gas highly concentrated, by installing a waste heat boiler, heat can be recovered as stream and hot air, a heat medium. -

Sustained 98% or higher treatment efficiency for exhaust gas

RTO's standard heat exchanger consists of two towers, with a heat storage material packed in each.

A target gas goes through the heat storage material in one tower and is heated to about 750°C, it then enters the reaction chamber in the upper part of the tower, where the gas is heated to 800°C or higher by a burner so that organic solvents contained in the gas are oxidized and decomposed. The cleaned hot air then flows into the other tower, moving down while releasing heat into the heat storage material. The damper at the intake repeatedly switches the operation between heat storage and release within the two towers.

With its consistent operation and with a treatment efficiency of 98% or higher, the RTO system is extremely useful for environmental measures. -

Applicable to environmental measures for exhaust gases in safety assessment testing

RTO has been applied to total systems including exhaust gas and water treatment.