Wind Tunnel Technology

Environmental Testing Equipment | Airflow Control Technology

What is environmental testing equipment?

Taikisha provides high-quality and compact equipment for high-precision environmental testing system with energy-saving based on our abundant experience.

What is airflow control technology?

In a development of automobiles, aerodynamic characteristics and driving performance should be measured before road test. Depending on the test items, actual driving environment reproduction is availble by creating airflow such as rectified air flow without vortex generation or air flow speed according to the engine speed.

- Want to reduce CO2 and enhance energy efficiency

- Want monitoring and control

Overview

A wind tunnel is used to artificially create wind. By measuring the aerodynamic characteristics of automobiles, high-speed trains, aircraft, and other structures in a wind tunnel, data for product development and design can be obtained.

In order to achieve better gas mileage from automobiles, improvement in aerodynamic characteristics and engine efficiency are required.

A wind tunnel is also an essential facility for the technologies contributing to the global environment protection.

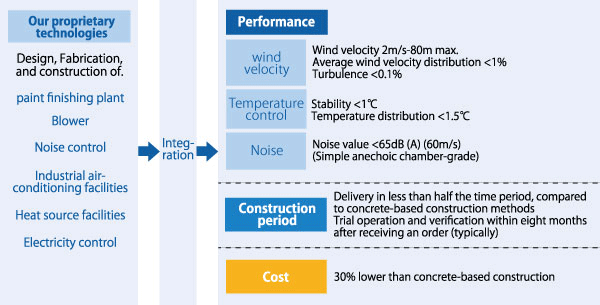

Drawing on all of our proprietary technologies, we use a high-precision, totally sheet-steel-based construction method to provide a Gettingen-type (circulative) high-performance wind tunnel at a low cost and within a short construction term.

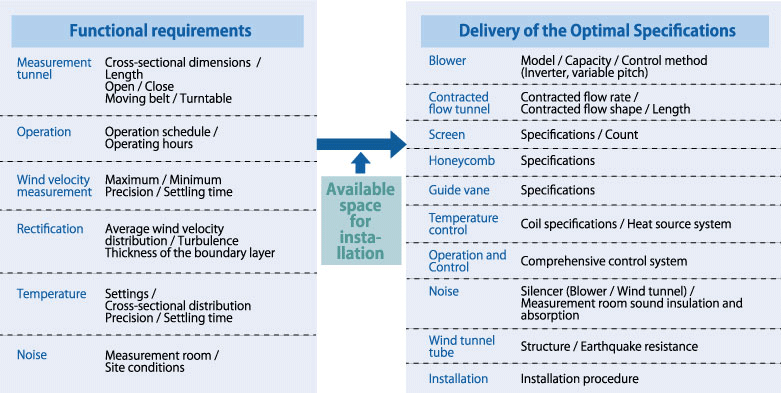

We propose the optimal plan based on your functional requirements, in accordance with the purposes of your experiments and the available space for installation.

Features

-

High-performance rectification

A wind tunnel for aerodynamic measurement needs to provide higher-order rectification with lower pressure loss and no eddy in any unit, including the contracted flow tunnel, honeycomb, screen, and guide vane.

-

Quick construction and low cost with totally sheet-steel-based construction

While most large wind tunnels are built with ferroconcrete, we adopt totally sheet-steel-based indoor construction with the emphasis on precision, cost, and delivery time. The wind pipe built with our advanced construction techniques utilizing sheet steel panels enables both greater robustness and quicker delivery.

-

Energy-saving temperature control system

Since air density depends on temperature, a consistent temperature is desirable for aerodynamic measurement. We have developed a temperature control system utilizing our energy-saving technologies.

Equipment

Automobiles speed tracking system

Making automotive engines more efficient

This system creates airflow in accordance with the rotation speed of an engine to simulate head wind a car experiences under real driving conditions. By precisely controlling the temperature and humidity in the wind tunnel, testers can simulate a variety of weather conditions.

Example Construction

| Test chamber dimensions | 14.3m (L) x 7.6m (W) x 3.5m (H) |

|---|---|

| Duct room dimensions | 8.8m (L) x 7.6m (W) |

| Temperature conditions | Control range: +10°C - +50°C, Control precision: ±0.5°C |

| Humidity conditions | Control range: 30% - 80% RH, Control precision: ±3% RH or better |

This system enables you to observe what happens to the body of a car and how its engine combustion and radiator performance change, when it runs in a certain environment for a long period of time.

Our vehicle speed tracking system contributes to the reduction of load on the global environment, by helping to improve the performance and safety of automobiles.

Wind tunnel facility for aircraft measurement

Wind tunnel facility for aircraft measurement

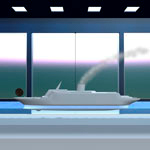

Wind tunnel facility for nautical measurement

Wind tunnel facility for nautical measurement

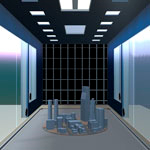

Wind tunnel facility for building-affected wind measurement

Wind tunnel facility for building-affected wind measurement

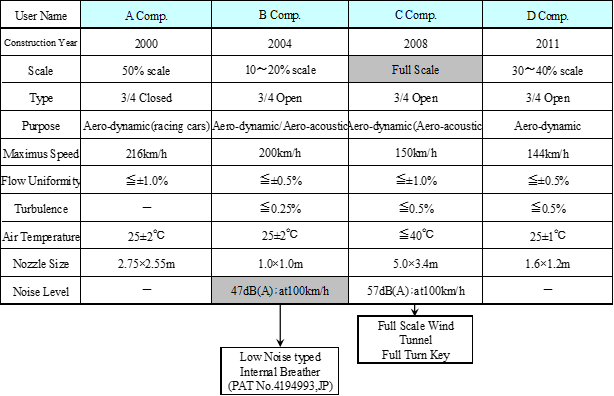

Major Delivery Records of Our Wind Tunnel Facilities

Furyusha, a wind tunnel for aerodynamic measurement of racing cars (Dome Co., Ltd.)

- Construction completed in November 2000

- Design and supervision: Dome Co., Ltd.

- Fabrication: Taikisha Ltd.

Furyusha under construction

Furyusha under construction