Pendulum Conveyor

Conveyor System | Pretreatment/electrodeposition overhead conveyors

What is our conveyor systems?

The conveyor system in the painting factory is an automatic transportation system that is involved in the entire process from receiving the car body from the welding factory, passing through the painting process, and handing over the car body to the assembly factory. Taikisha supports various transportation systems, from the hanger / trolley method that has been used in Japan for a long time to the skid method that is mainly used in Europe. In addition, it can be used not only for automobile bodies but also for painting systems for plastic parts.

What is pretreatment/electrodeposition overhead conveyors?

The pretreatment and electrodeposition process is the first process in a painting factory. Overhead conveyor is used in the process. There are different types depending on their method and capacity.

- Want to lift productivity

- Want to reduce CO2 and enhance energy efficiency

- Want to make the best use of limited spaces

- Want to improve labor environments and achieve automation

Overview

This conveyor is a skid-type overhead conveyor applied to pretreatment and electrodeposition processes.

The treatment process is chain transportation.

It is transported by the roller bed method. The work (automobile body) is mounted on the skid. The skid is automatically mounted by two U-shaped arms attached to the chain.

The empty hanger to be returned is returned with the U-shaped arm folded at the bottom of the device.

Pendulum hanger with Body and Skid

Pendulum hanger with Body and Skid

Entrance at dipping tank

Entrance at dipping tank

Entrance/Exit at ED tank

Entrance/Exit at ED tank

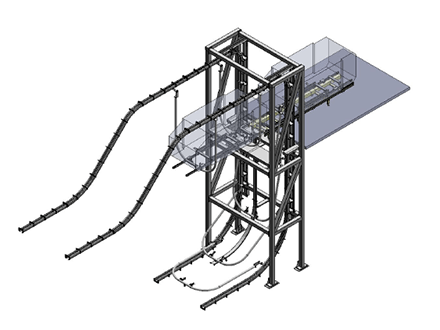

Overview at Entrace Tower

Overview at Entrace Tower

Features

We can handle up to 80 JPH (Jobs per hour) production. The dip tank entry / exit angle is 45 degrees. In the treatment process, it is transported by the chains on the left and right of the device. Before and after the treatment process, it will be transported by a roller bed. Transport operation is performed only when a skid is detected. The U-shaped arm is returned with the arm folded under the treatment device, so empty return line is not required. In addition, arm maintenance can be handled at the bottom of the treatment device. The skid goes through the treatment process with the work (automobile body) mounted on it, so there is no need to transfer it.