Health & Safety Management

Corporate Health & Safety Policy

Basic Principles of Industrial Health and Safety

Based on an understanding of the importance of human life as its basic principle, Taikisha thoroughly implements safety-first planning and construction and fulfills its social responsibilities as a company in the construction industry out of respect for the law. Taikisha aims to protect the health and lives of employees and workers and makes efforts to build a more comfortable working environment.

Action Guidance

- Critical or public disaster prevention

- Development of a comfortable working environment

- Improvement of health & safety management guidelines

- Improvement of health & safety management abilities of overseas group companies

Monitoring of Safety Activity Results

Taikisha has established its own Taikisha Occupational Health & Safety Management System with respect for human lives and a law-abiding spirit as its basic principle.

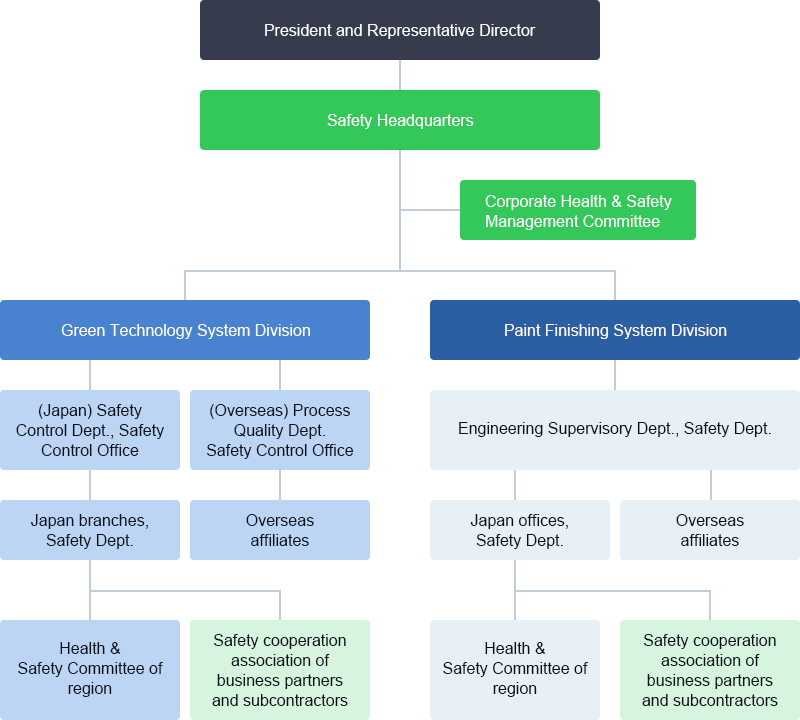

Taikisha has established the Safety Headquarters in its Headquarters and the Safety Control Department in each of its business divisions, and they support safety activities of Branch Offices and Offices while supervising and managing industrial safety of the entire group.

Health & Safety Management System and Activities

Taikisha measures and monitors the effects of safety activities by using a frequency rate that indicates the frequency of industrial accidents and a severity rate that indicates the severity of accidents as safety indicators. The transition of these indicators is as follows.

Frequency rate: This indicates the frequency of occurrence of industrial accidents, which is calculated based on the number of deaths and injuries due to industrial accidents (accidents involving at least four days of lost work time according to the criteria of the Ministry of Health, Labour and Welfare) per 1,000,000 cumulative hours worked.

Severity rate: This indicates the degree of seriousness of the accident, which is calculated based on the number of work-days lost per 1,000 cumulative hours worked.

Scope: Taikisha's construction sites (employees on a non-consolidated basis and subcontractors)

Frequency and Severity Rate Indicators for the Past Five Years in Japan

unit: %

| 2018 | 2019 | 2020 | 2021 | 2022 | |

|---|---|---|---|---|---|

| Frequency rate | 0.381 | 0 | 0.536 | 0.411 | 0.12 |

| Severity rate | 0.025 | 0 | 0.010 | 0.022 | 0.001 |

Number of Industrial Accidents Occurred

unit: Cases

| 2018 | 2019 | 2020 | 2021 | 2022 | |

|---|---|---|---|---|---|

| Fatal/serious industrial accidents | 0 | 0 | 0 | 0 | 0 |

| Industrial accidents involving at least four days of lost work time | 3 | 0 | 4 | 3 | 1 |

Efforts for Accident Prevention

Taikisha created the videos of past accident cases, including crashes and falls, and have begun viewing them to prevent similar accidents. We plan to expand these videos to our overseas offices in the future.

Efforts for Improvement of Industrial Health & Safety Management in Overseas Affiliates

Every two years, the Safety Headquarters conducts an audit of each overseas office and workplace to ensure that they are in compliance with occupational health and safety management activities based on each site's health and safety management system.

Conferences and Safety Training by Inviting Overseas Local Staff

On an annual basis, engineering and safety staff of overseas affiliates are assembled in Japan to be provided with safety education, in an effort to improve their safety management skills. In FY2023, we invited technical staff from overseas affiliates to Japan for the first time in four years, and held a meeting of safety managers of overseas affiliates group safety training.

Safety Education Items for Staff Members of Overseas Business Offices

- Safety activity guidance

- Presentation of safety activities of each country

- Group discussion

- Safety patrol training

- Crisis experience training

- Education on various safety management capabilities

- Opinion exchange meeting, etc.

Development of Human Resources for Industrial Safety and Health

Taikisha implements the following initiatives with the aim to develop safety staff in Japan and overseas.

Establishment of information-sharing website for all the safety staff

An information-sharing website was launched for all the safety staff including overseas staff. Safety information and manuals are available in Japanese, English and Chinese.

Staff training on safety

In FY2022, we conducted safety training five times in Japan for 295 young employees, who were candidates for general managers, as position-specific employee training. We also conducted e-learning twice for 26 overseas staff members with the aim of raising safety awareness. In FY2023, we are planning to conduct safety training, which will include hazard experience using VR, for new employees, employees of respective branch offices and bases, and subcontractors. For overseas staff members, we will continue to conduct e-learning twice, and plan to deliver videos of some accident cases that occurred at our overseas affiliates. Furthermore, in this fiscal year, we started to deliver e-mails for safety reminders to overseas affiliates twice a month in order to foster safety awareness.

Implementation of general training including safety

The Company set a rule that requires each office, etc. to provide education to its staff and partners about the systems and other matters in accordance with the “education manual for employee preparatory training, business partner training, staff preparatory training and site staff training,” and planned or conducted about 15 different safety trainings at various offices including Safety Headquarters. The Safety Headquarters also conducts training for new staff and new managers as well as various other level-specific training sessions once a year.